- Home

- About

- Products

- Product Testing

- Application

- Services

- Information

- Contact

Views: 1560 Author: Site Editor Publish Time: 2020-07-10 Origin: Site

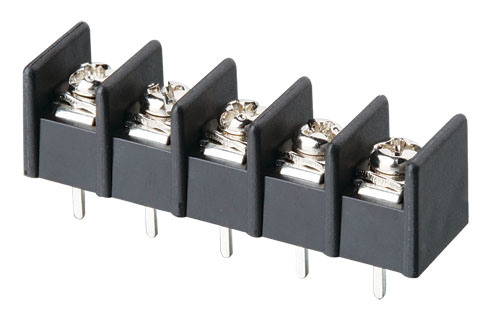

Terminals can be said to be the most used in power supply equipment factories, electrical equipment factories, mechanical equipment factories and LED factories. Terminals will encounter problems with poor insulation in many cases in actual use. The reasons for these problems will be analyzed below.

Insulators not only play an insulating role, but also usually provide accurate centering and protection for protruding contacts. Colleagues also have the functions of installation and positioning, and locking and fixing on equipment. Poor fixation, light affects the reliability of the contact and causes instant power failure, the most serious is the product disintegration. Disassembly refers to the abnormal separation between the plug and the socket, and between the pin and the socket caused by the unreliable structure of the terminal in the mated state due to materials, design, and technology. It will cause serious consequences for control system power transmission and signal control terminals. Due to unreliable design, wrong material selection, improper selection of molding process, poor quality of heat treatment, mold, assembly, welding, etc., and poor assembly will cause poor fixing. In addition, the appearance is poor due to peeling, corrosion, bruising, flashing of the plastic shell, cracking, rough processing of the contact parts, deformation and other reasons. Poor interchange due to excessively poor positioning and locking fit dimensions, poor consistency in processing quality, and excessive total separation force are common and frequently-occurring diseases. These kinds of faults can generally be found and eliminated in time during inspection and use.

The role of the insulator is to keep the contacts in the correct position and to insulate the contacts, the contacts and the housing from each other. Therefore, the insulation must have excellent electrical properties, mechanical properties and process molding performance. Especially with the widespread use of high-density, miniaturized terminal blocks, the effective wall thickness of insulators is getting thinner and thinner. This imposes more stringent requirements on insulation materials, injection mold accuracy and molding processes. Due to the presence or absence of excess metal on the surface of the insulator, surface dust, flux and other contamination and moisture, organic material precipitates and harmful gas adsorption films fuse, with the surface water film to form ionic conductive channels, moisture absorption, mold growth, aging of insulation materials, etc. which will cause short circuit, leakage, breakdown, low insulation resistance and other poor insulation phenomena.

The metal conductor inside the terminal is the core part of the terminal . It transmits the voltage, current, or signal from the external wire or cable to the corresponding contact piece of the connector. Therefore, the contact must have an excellent structure, stable and reliable contact holding force, and good electrical conductivity. Due to the unreasonable structural design of the contact, incorrect selection of materials, unstable mold, poor processing size, rough surface, heat treatment and electroplating, surface treatment processes such as irrational, improper assembly, poor storage and use environment, and improper operation and use will cause contact in contact sites and mating sites cause poor contact.

If you pay more attention to the use environment of the device in your life, carefully check the instructions for use of the device, and handle the dust in a timely manner, you will try to avoid the bad situation of the terminal.

As a leader in this industry, our company Cixi Kefa Electronics Co., Ltd is a manufacturer founded in 1990 with great reputation in many years. We specialize in terminal block, connectors and precision moulds. If you have any interest, please click the following website to learn more.

http://www.cnkefa.com/