- Home

- About

- Products

- Product Testing

- Application

- Services

- Information

- Contact

Views: 2508 Author: Site Editor Publish Time: 2020-09-04 Origin: Site

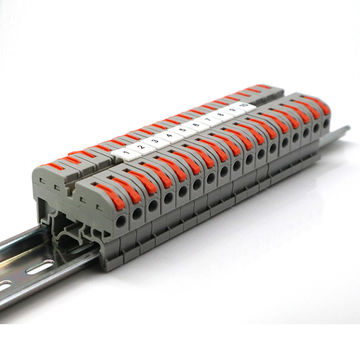

Terminal is a tool for wiring. It has been more than a hundred years since the terminal was invented. The rapid development of terminals indicates a large demand in the market. The use of terminals for wiring not only simplifies the wiring mode, makes the wiring simple and fast, but also improves the safety of the wiring.

If the terminal needs to be connected to a large number of wires, it is necessary to mark the terminal at this time to prevent wire installation errors and cause accidents. Here are two accidents caused by electrical wiring errors. In March 2018, when the staff of a power plant carried out equipment inspection, the circuit breaker tripped, causing the equipment to stop running. The reason is that the operator reversely connected the 5022 circuit breaker, the 5023 circuit breaker and the 5021 circuit breaker's trip wire, and the terminal on the positive side of power supply was also reversely connected.

If the operator's vigilance is not high, the technical skill is insufficient, the plan is not meticulous, the safety measures are not comprehensive, it is prone to wiring errors, resulting in safety accidents. In order to prevent the occurrence of similar problems, the following needs to be emphasized:

1. The operators should pay attention to the test work of the power grid and strictly follow the rules to carry out the operation. The operator should perfect the test plan and carry out the calibration and test according to the requirements of the grid regulations. The operator should strengthen the inspection of the external lines of the modified equipment. Before starting the equipment, the voltage test and current test should be carried out on all the modified voltage and current circuits to ensure the wiring is correct.

2. The operators should conscientiously carry out risk assessment, carefully verify wiring, and ensure that safety measures are implemented in place. Before starting the equipment, carefully check the wiring to ensure the correctness of the wiring, and fully consider the consequences of the wiring not in accordance with the drawings. Standardize the implementation process and acceptance procedure of relay protection safety measures to ensure the correct wiring.

3. Strengthen the management of the test site, conscientiously carry out the personnel arrangement and responsibility of the test work link, and make clear the operation focus and matters needing attention of the operators and test personnel during the test process. In the process of the test, it is necessary to strengthen the monitoring of the operation of the protective device, find the warning signal of the protective device in time, stop the test immediately when the abnormal signal is found and report to the command, and check the device before continuing the test.

Although the terminal is small in size, it is a bridge connecting the external equipment with the main equipment. The correct use of terminals can greatly improve the working efficiency and ensure the safe operation of the circuit. The wrong use of the terminal will cause circuit failure, resulting in unnecessary accidents.